L’INNOVATION DANS LA TRANSFORMATION DE POMME DE TERRE

Nous valorisons les pommes de terre déclassées grâce à notre amidonnerie mobile écoefficiente.

Nos différents partenaires

Transformez vos rebuts de pomme de terre en ressources — Amidon local, solutions globales.

Nous valorisons les co-produits agricoles en ingrédients amylacés à haute valeur ajoutée, pour des applications alimentaires et industrielles durables.

Collecte

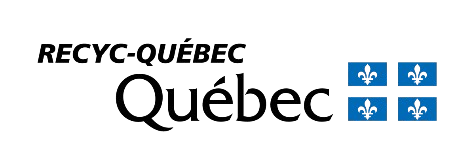

Nous réceptionnons vos pommes de terre déclassées directement sur votre exploitation.Lavage & Broyage

Les pommes de terre sont nettoyées et broyées pour extraire la pulpe.

Extraction

L'amidon est séparé de la pulpe par centrifugation et filtration.

Séchage

L'amidon est séché pour obtenir une poudre fine prête à l'emploi.

Technologie Exclusive en Amérique du Nord

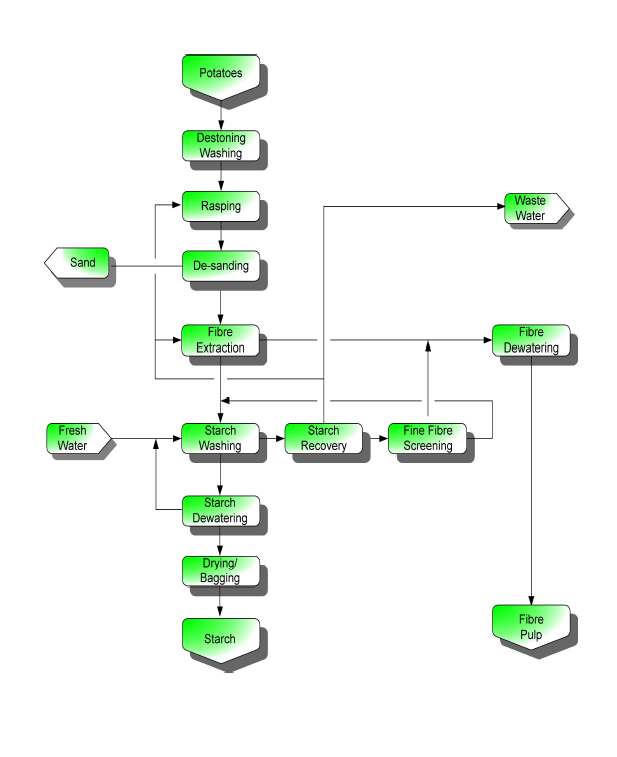

Grâce à notre technologie exclusive, nous déployons une amidonnerie mobile écoefficiente, capable d'extraire de l'amidon natif directement sur les lieux de production.

Cette unité mobile, compacte et performante, réduit les coûts de transport, optimise la consommation énergétique et améliore la qualité des produits transformés.

Notre unité mobile comprend :

Le lavage, le triage, le broyage, la séparation des fibres, l'extraction de l'amidon et sa déshydratation

Un système intégré de traitement et de recyclage des eaux usées

Une capacité optimale pour la valorisation locale des pommes de terre déclassées et des résidus agricoles

Une vision durable en mouvement

Plongez au cœur de notre solution mobile et voyez comment nous transformons les déchets agricoles en opportunités écologiques.

Avantages de notre solution mobile

Réduction des coûts logistiques

Plus besoin de transporter les pommes de terre déclassées vers une usine fixe.

Réduction des coûts logistiques

Plus besoin de transporter les pommes de terre déclassées vers une usine fixe.

Réduction des coûts logistiques

Plus besoin de transporter les pommes de terre déclassées vers une usine fixe.

Réduction des coûts logistiques

Plus besoin de transporter les pommes de terre déclassées vers une usine fixe.

Que vous soyez producteur ou transformateur , notre solution vous accompagne pour maximiser vos ressources et vos résultats.

Évaluez votre impact écologique

Simulez les économies de déchets et de CO₂ que vous pouvez réaliser en transformant vos rebuts agricoles avec Exclusivert.

Notre regard sur l’innovation durable.

Découvrez nos articles, conseils et actualités autour de la valorisation agricole, des bioplastiques et de la transition écologique.

Les articles récents

The latest industry news, interviews, technologies, and resources.

Questions fréquentes

Trouvez rapidement des réponses aux interrogations les plus courantes sur nos services, notre technologie et nos partenariats.

Qu’est-ce que l’amidon natif produit par Exclusivert ?

Il s’agit d’un amidon extrait localement à partir de pommes de terre de grade 2 et 3. Pur, traçable et non modifié chimiquement, il est idéal pour les applications agroalimentaires, industrielles et techniques où la simplicité et la naturalité sont requises.

Quelles sont les différences entre vos amidons natifs et modifiés ?

L’amidon natif est la version brute, extraite sans transformation chimique. Les amidons modifiés (acétate, cationique, réticulé, etc.) sont adaptés pour renforcer certaines propriétés (résistance thermique, adhésion, viscosité).

Vos produits sont-ils compatibles avec les normes environnementales ?

Absolument. Nos bioproduits sont conçus pour s’intégrer dans des chaînes de production à faible empreinte carbone. Ils sont biosourcés, biodégradables et traçables de la ferme à la transformation.

Qu’est-ce qu’une amidonnerie mobile ?

C’est une technologie de transformation installée dans un conteneur mobile qui peut être déployée directement sur les lieux de production agricole ou de transformation.

Quels types de résidus de pomme de terre sont valorisés ?

Nous utilisons des rebuts de transformation (épluchures, brisures, boues amylacées) ainsi que des pommes de terre déclassées (grade 2 et 3).

Comment garantissez-vous la qualité de l’amidon extrait dans une unité mobile ?

Grâce à un protocole de traitement optimisé et des tests qualité sur place, notre amidon atteint les standards industriels. Le raffinage est ensuite fait dans notre unité centralisée.

Je suis producteur : que gagne-je à collaborer avec vous ?

Vous transformez un coût (vos déchets) en opportunité. Nous vous proposons d’utiliser notre unité mobile chez vous, et nous vous rachetons l’amidon humide produit à un prix équitable.

Dois-je investir dans des équipements pour accueillir votre unité mobile ?

Non. Vous devez simplement disposer d’un espace plat, d’un accès à l’eau et à l’électricité. Nous vous accompagnons dans l’installation.

Puis-je recevoir un échantillon de vos produits ?

Oui, nous proposons l’envoi d’échantillons d’amidon natif ou modifié selon vos besoins industriels.

Pourquoi vos produits sont-ils plus durables que l’amidon importé ?

Nos amidons sont produits localement à partir de rebuts ...)

Quels sont les impacts environnementaux de votre solution ?

Nous réduisons les émissions liées au transport, diminuons les déchets agricoles et contribuons à une agriculture zéro perte.

Quels sont vos formats de livraison ?

Amidon natif en format humide (IBC ou vrac) ou séché en sacs de 25 kg. L’amidon modifié est livré selon les spécifications techniques.

Quels délais de livraison offrez-vous ?

Québec : 48–72 h. Canada/États-Unis : livraison rapide via transporteurs spécialisés.

Travaillez-vous avec des centres de recherche ou universités ?

Oui. Nous avons des partenariats actifs avec des universités québécoises, des CCTT et d’autres centres de recherche et laboratoires pour le développement d’amidons techniques et de bi Bioplastiques.

Proposez-vous des solutions sur mesure pour les industriels ?

Oui. Nous adaptons nos amidons modifiés selon votre fiche technique (viscosité, pH, comportement thermique…).