An eco-efficient mobile starch factory

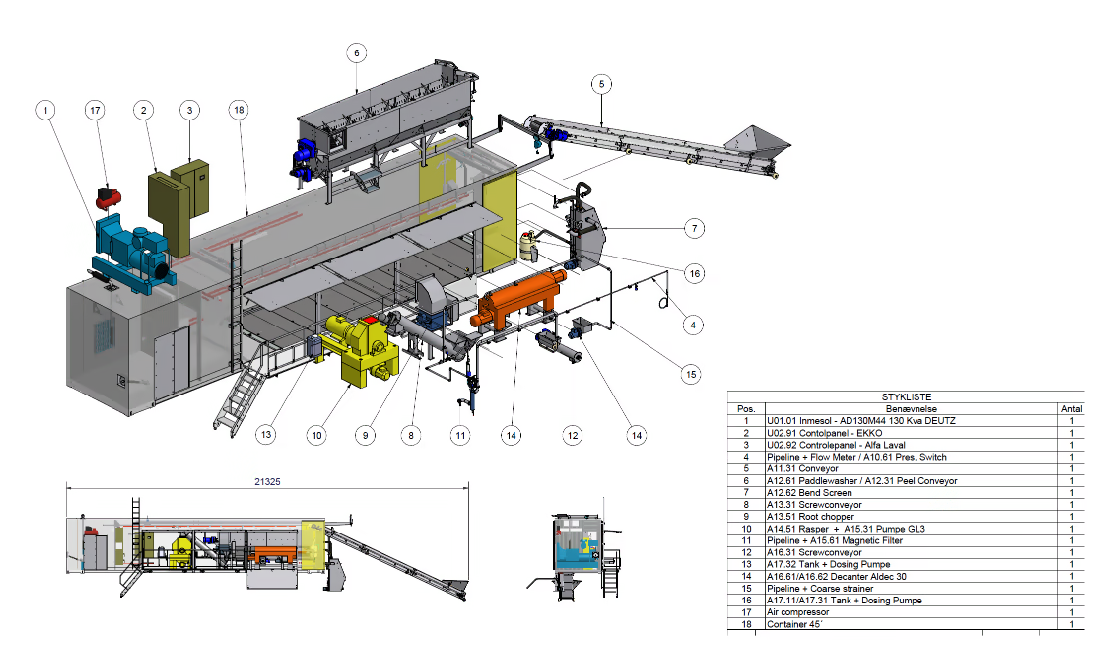

On the technological level, Exclusiv'Or innovates by deploying a mobile unit for extracting native starch from a 45-foot container unit containing all the modules required for extraction. This mobile unit is designed to be efficient in terms of yield, energy consumption, water consumption, and environmental (wastewater discharge without treatment).

-

All modules (i.e. cleaning, washing, grating, grinding, fiber extraction, starch washing, starch dehydration, drying, bagging), eco-designed.

-

A water treatment and recirculation system is annexed to it.

-

The whole optimized for the varieties of potato residues available in Quebec and Canada.

Our mobile units will therefore be less energy-intensive, allowing the recovery of starch contained in water (treatment system), and reducing the volume of water required (water recirculation system).

Bioplastic granules and blown films based on native potato starch

The extracted native starch is used to formulate bioplastic granules by twin-screw extrusion. These granules are 100% bio-sourced, contain only renewable ingredients (e.g. bio plasticizers, bio-additives and bio-copolymers), and are biodegradable and compostable.

The granules are then used to develop blown films by blow extrusion intended, initially, for potato packers. Exclusiv'or is able to control the degradation rate of the films and will be able, in a few months, to adjust the latter to the required service life of the application (e.g. degradation after 3 months, 6 months or more).